Cause analysis and resolution for a noisy gearbox

Activity duration : 300 h

INPUT

Research the causes of noise found in a production gearbox and propose remedial design actions

PROCESS

Analysis of operating conditions, gear calculation, modal FEA of the casings, development of a design proposal on the project

OUTPUT

Calculation reports, updating tables and 3D models of some parts

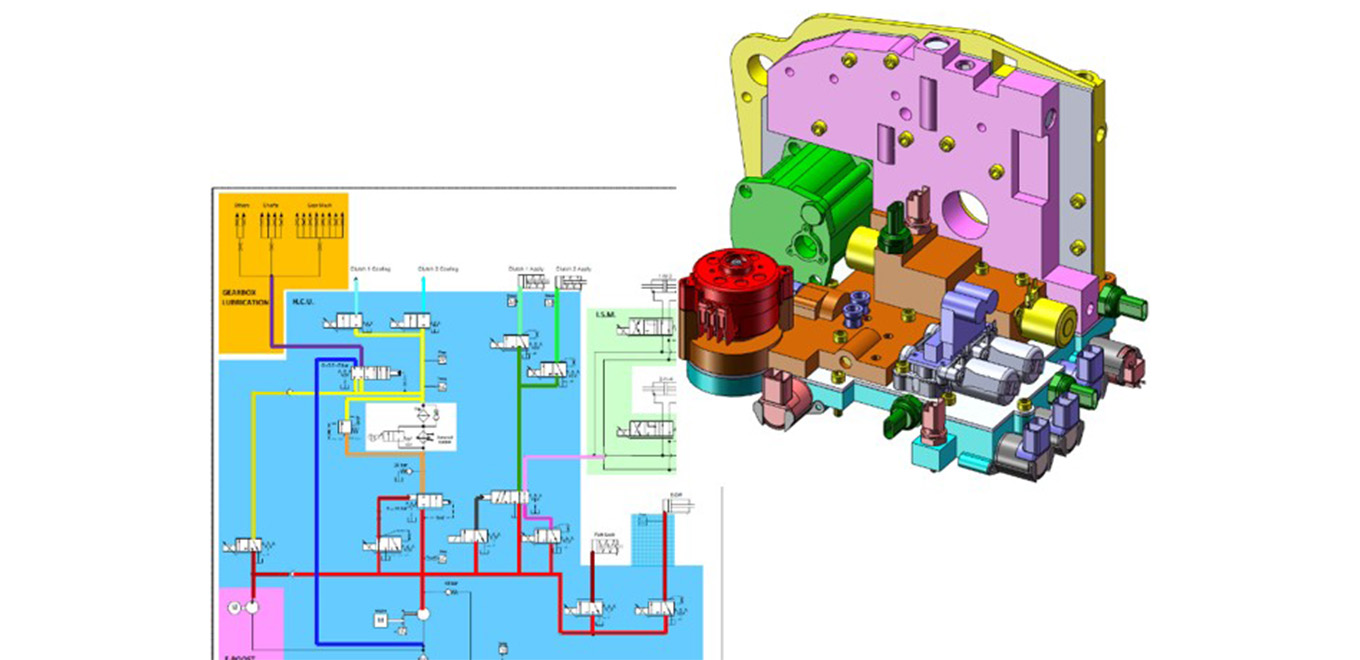

Preliminary study of a DCT for a series sports car

Activity duration : 1800 h

INPUT

First design of hydraulics and layout of DCT for a high performance sports car

PROCESS

Analysis, calculation and setting of the circuit and subsystems of the DCT hydraulic module; preliminary layout study and co-design of system integration with the gearbox manufacturer

OUTPUT

3D model of study layout, reports

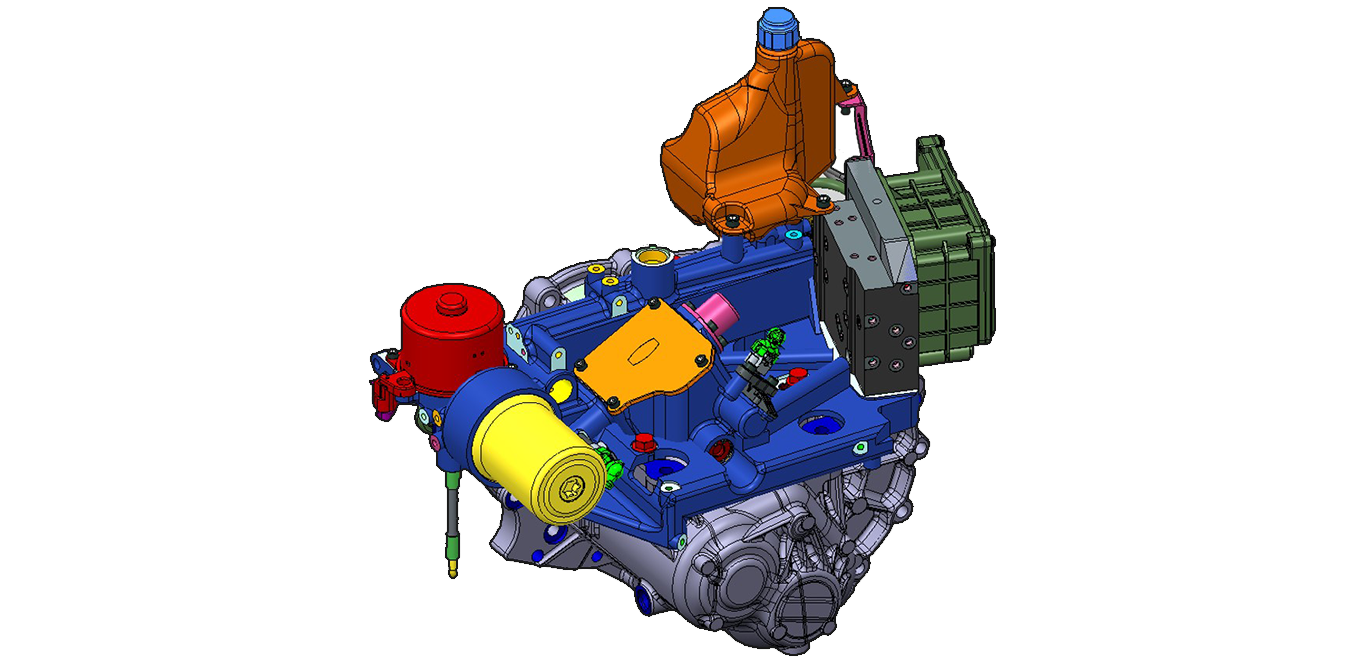

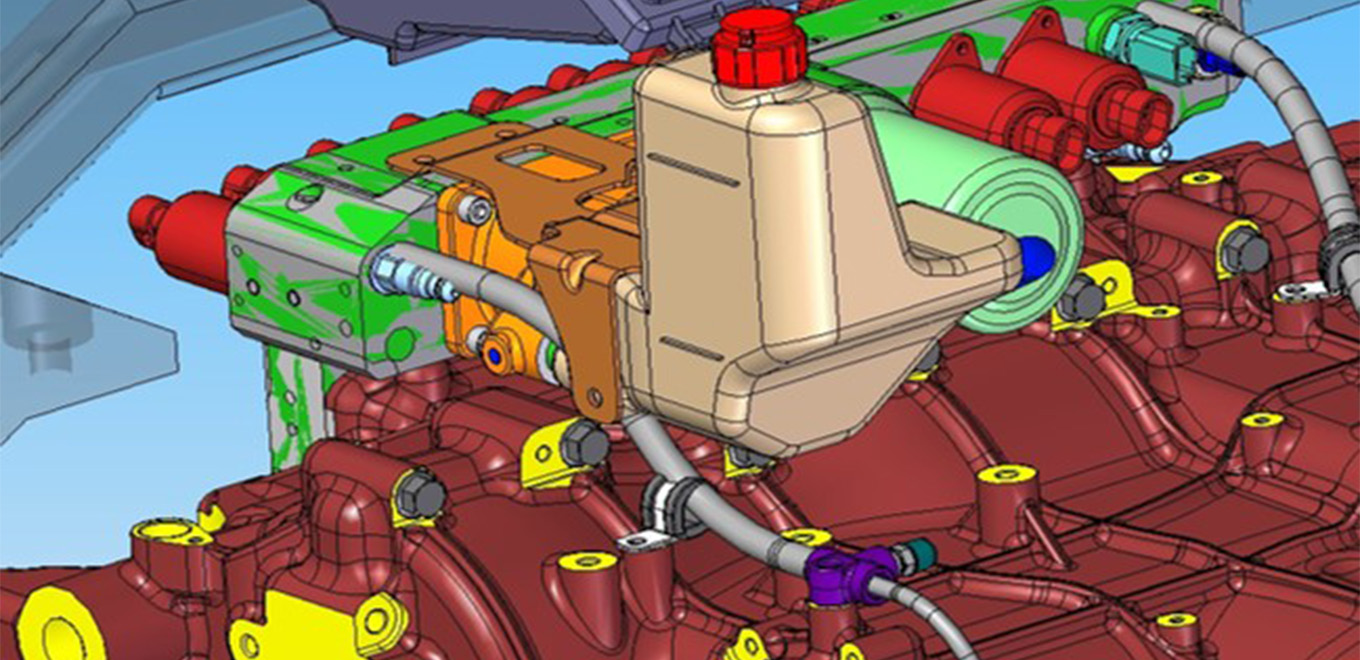

Preliminary study of a hydraulic AMT

Activity duration : 2000 h

INPUT

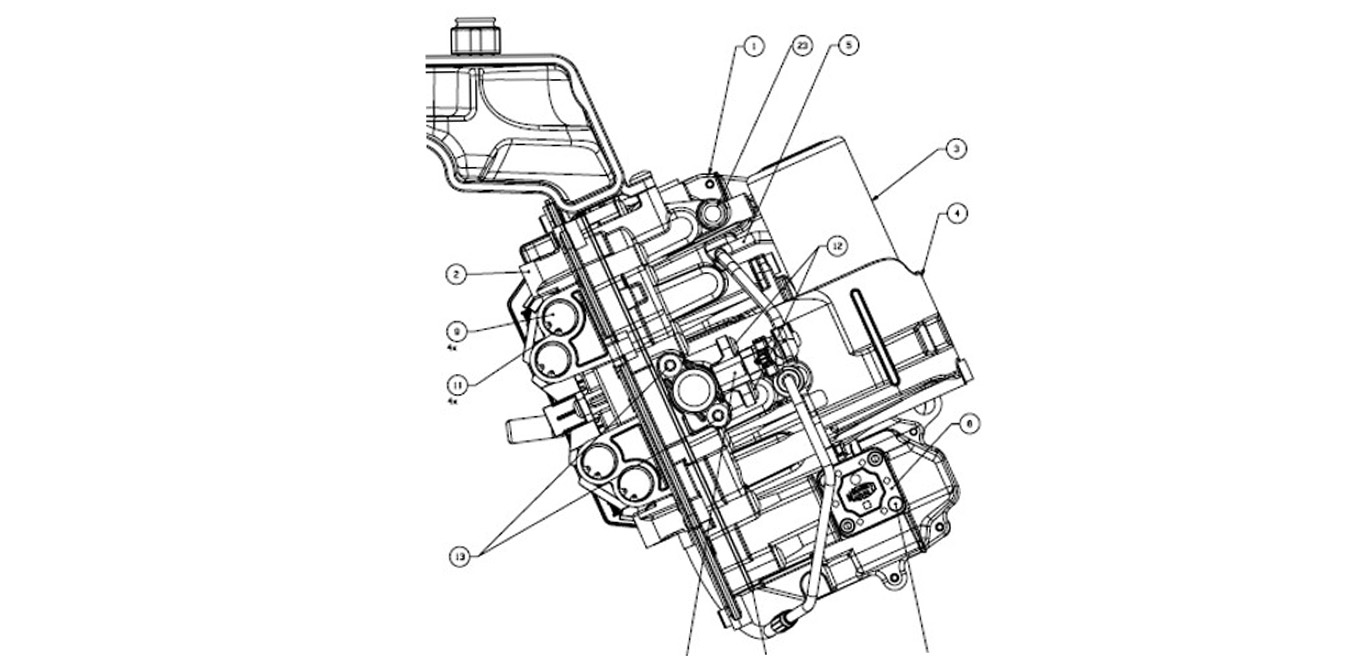

Carry out feasibility study of hydraulic AMT application on manual gearbox for new mass-produced car

PROCESS

Preliminary study and progressive project refinements (direct relationships with the end customer’s work group); layout analysis and integration of the unit under the bonnet; integration of current production carryover parts and subsystems; industrialization pre-analysis

OUTPUT

3D model of study layout, reports

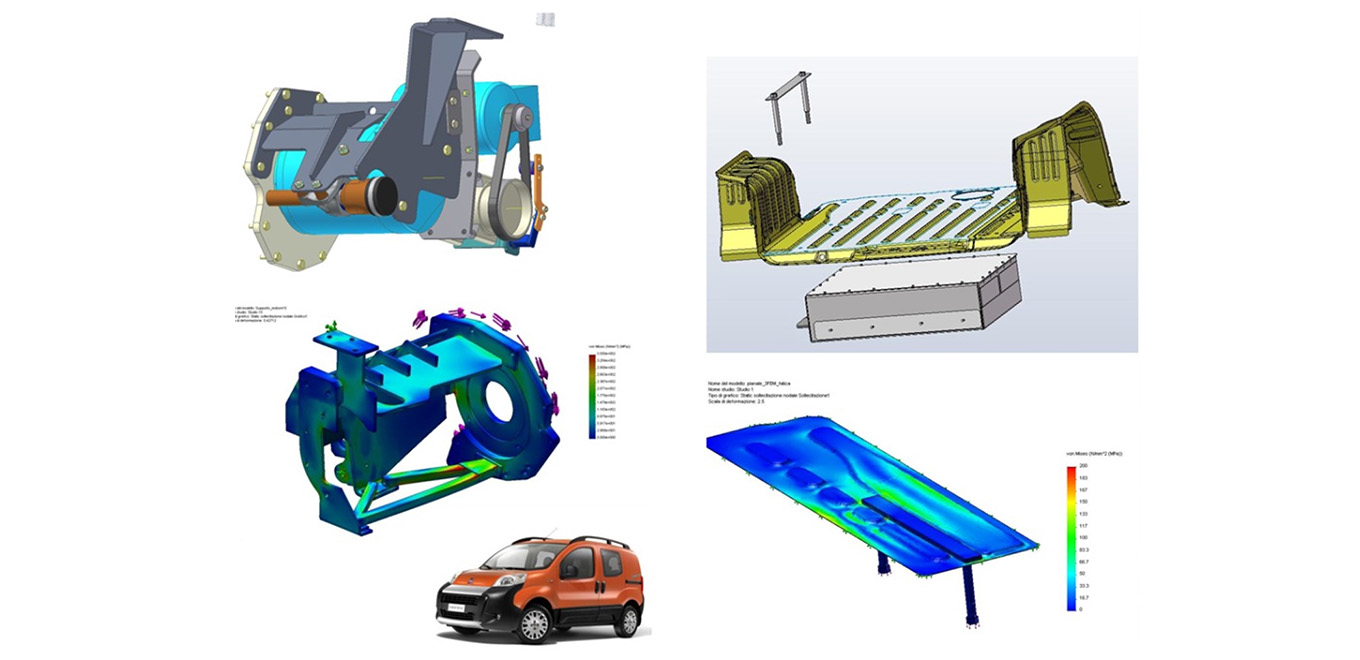

Preliminary study of a electric AMT

Activity duration : 1500 h

INPUT

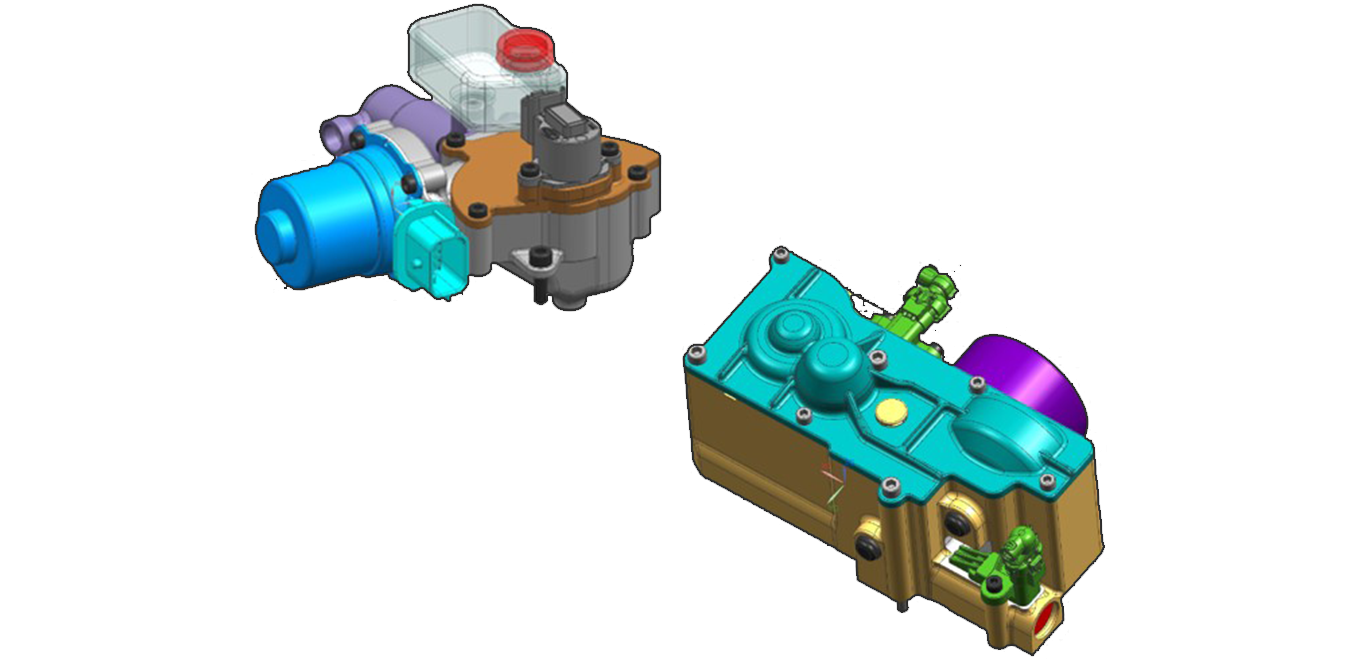

Carry out feasibility study of electric AMT application, split into two modules (clutch and gearbox) for new mass-produced car

PROCESS

Preliminary conceptual study and progressive project refinements; analytical and FEA calculations where necessary; industrialization pre-analysis; realization of different feasibility variants

OUTPUT

3D model of study layout, reports

Problem solving on a mass-produced DCT

Activity duration : 3000 h

INPUT

Analyze and solve technological and functional problems of DCT application on mass-produced vehicles

PROCESS

Drawing analysis of the issue; calculation/modeling activities for problem evaluation; formulation of proposals for a concrete and sustainable solution

OUTPUT

Calculation sheets, 3D models, drawings, report

Design and prototype of a hydraulic e-clutch

Activity duration : 1000 h

INPUT

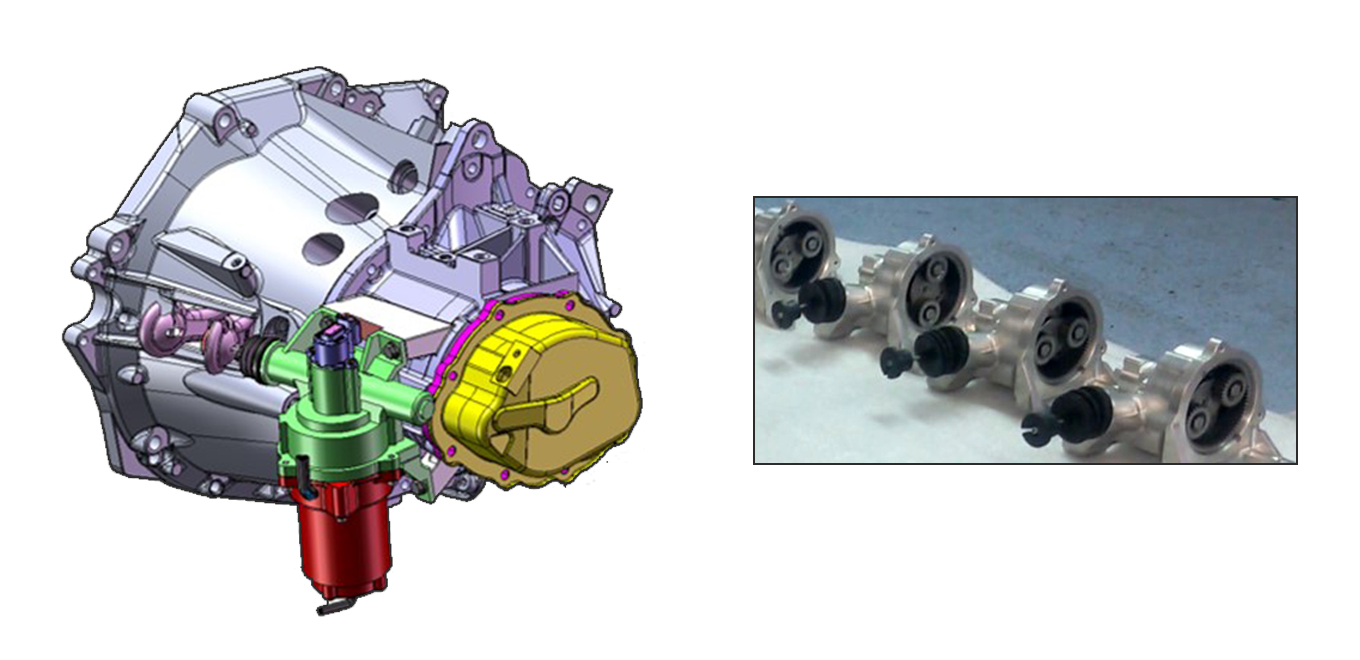

Study the concept, feasibility and prototype design of a hydro-mechanical e-clutch unit; create mechanical part prototype

PROCESS

Assembly modeling and gradual refinements; carrying out necessary calculations; co-design with interface suppliers and end customer; shared definitive study and construction tables; construction of mechanical parts and assembling of 5 groups

OUTPUT

3D models, drawings, report and 5 physical protos

Hybrid van transmission design

Activity duration : 2000 h

INPUT

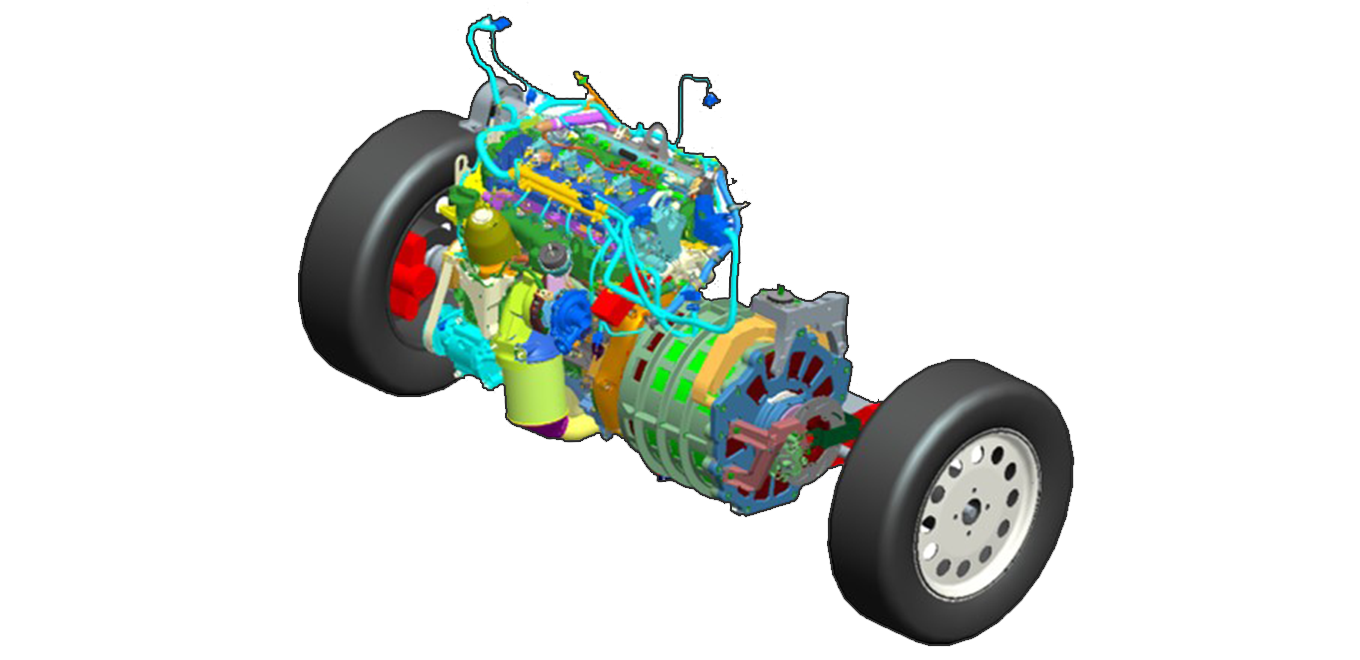

Designing an electric-diesel hybrid transmission to equip a van

PROCESS

Preliminary design and following refining steps Layout analysis and assembly integration under bonnet Critical parts FEA calculations Gears, bearings and shafts calculation

OUTPUT

General and detailed arrangement drawings Calculation report

Electro-hydraulic actuator system design

Activity duration : 800 h

INPUT

Fitting an actuator system concept to a sport car gearbox

PROCESS

Layout analysis and available volumes evaluation Preliminary design and following refining steps

OUTPUT

Detailed arrangement drawings of parts and functional assemblies

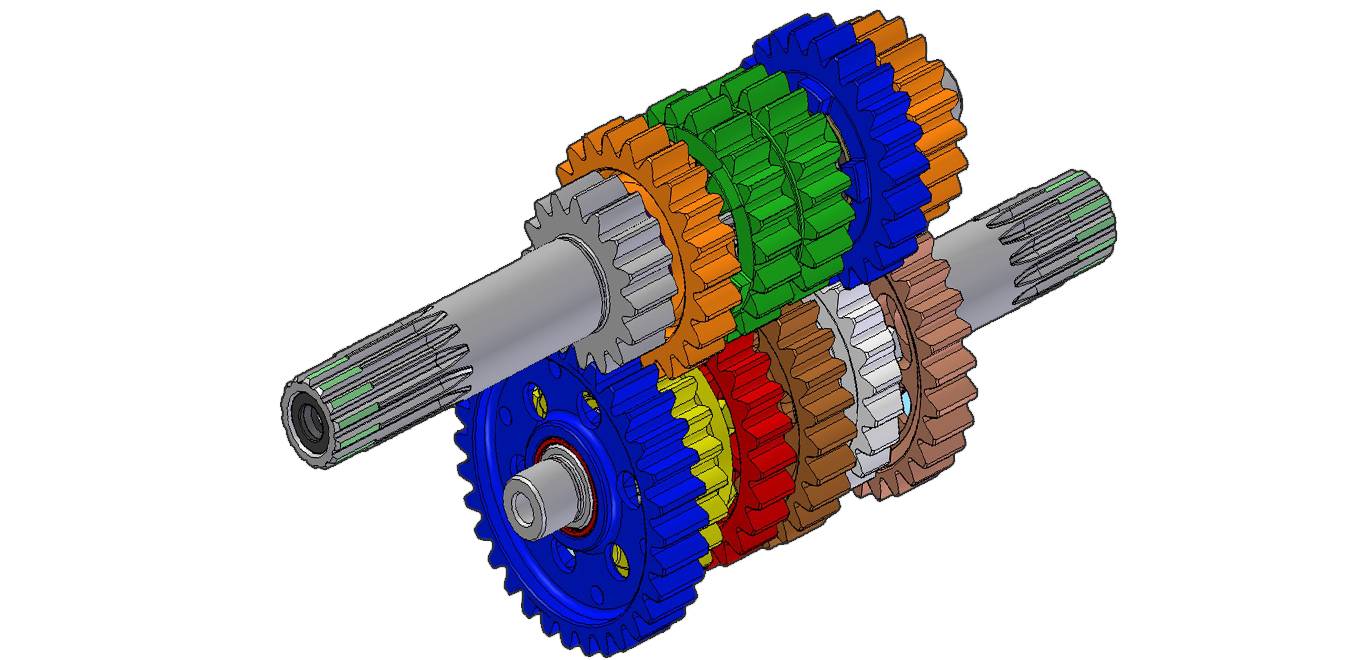

Motorcycle gearbox design

Activity duration : 1500 h

INPUT

Designing a dog-clutch gearbox for a road motorcycle

PROCESS

Gear calculation with specialized software and gear profile optimization 3D design of shafts, gears and box FEA calculation of dog-clutch Gear engaging desmodromic system design

OUTPUT

General and detailed arrangement drawings Calculation report

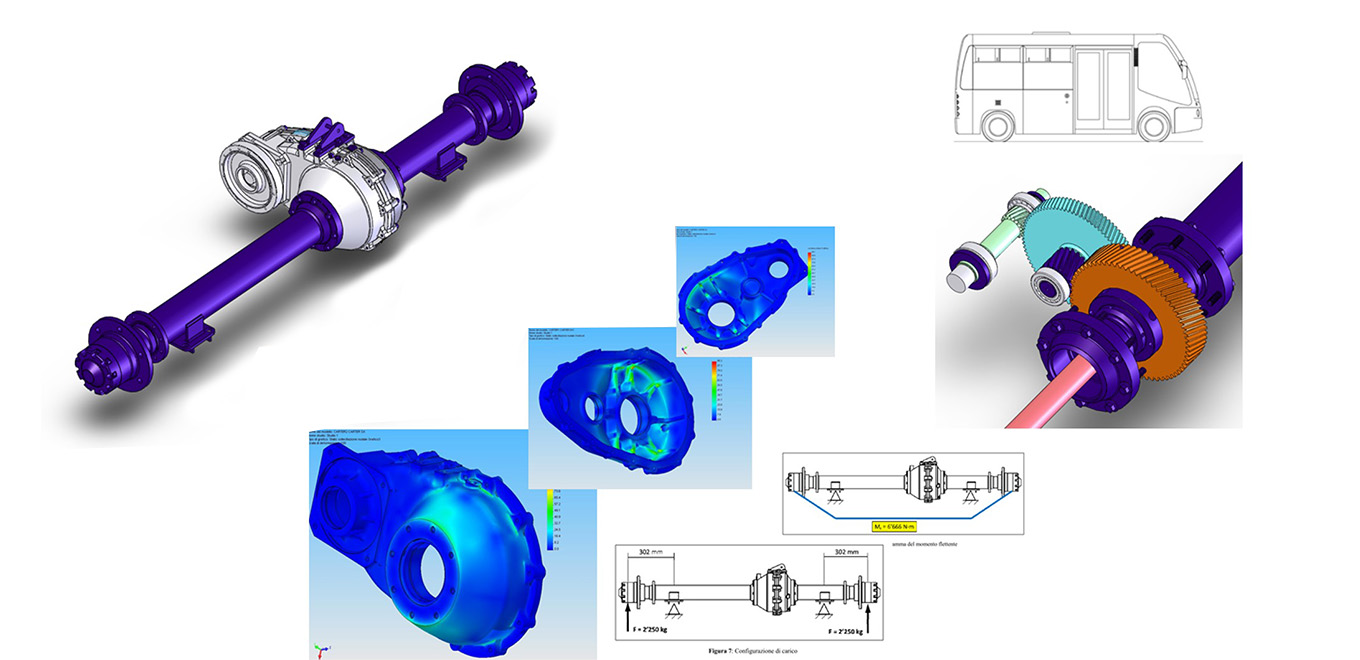

Electric bus axle analysis

Activity duration : 450 h

INPUT

Making a structural analysis on axle and calculate gear system

PROCESS

Load conditions setup with customer agreement FEA analysis on structural parts Gears design and bearings calculation

OUTPUT

Gears data table, castings improvement advices Final report

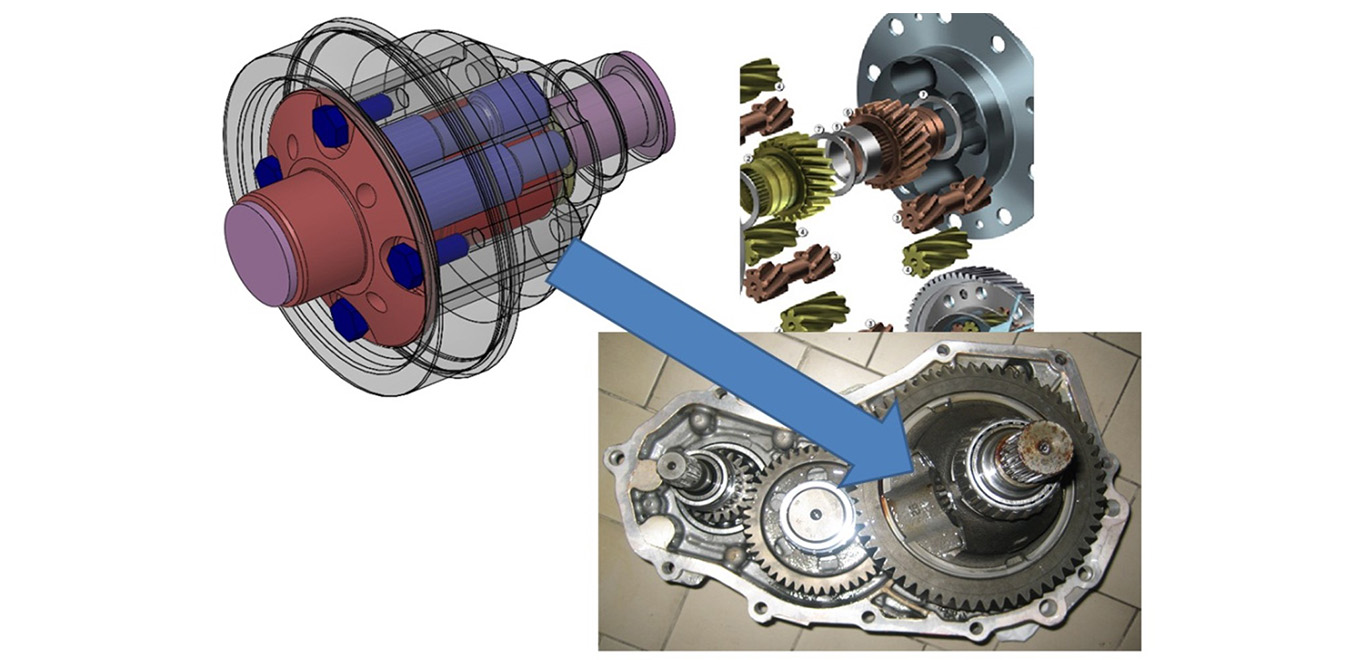

Self-locking differential implementation on electric vehicle

Activity duration : 430 h

INPUT

Transforming a free differential automotive transfer into a self-locking one

PROCESS

Layout measurement of volumes available inside original case 3D design of self-locking differential Differential gears calculation Drawings and prototype building

OUTPUT

Supply of a new transfer with self-locking differential, ready to be installed on the vehicle

Design of conversion kits for thermal to electric vehicles

Activity duration : 250 h

INPUT

Design a kit for the transformation of vehicles powered by thermal engines into Z.E. electric vehicles

PROCESS

Vehicle surveys of available spaces; installation study of the electric motor unit and related auxiliaries; underfloor battery pack installation study; FEA calculations of critical components

OUTPUT

Mechanical kit drawings; support during physical assembling

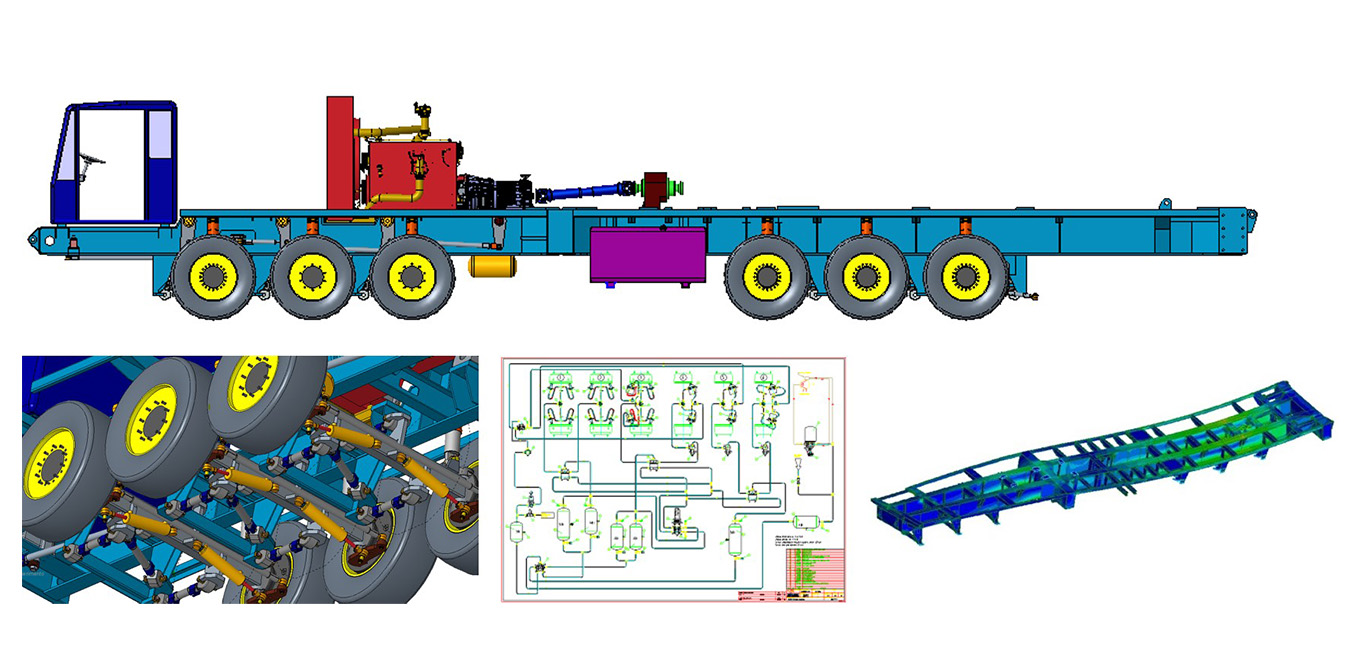

Drilling carrier design

Activity duration : 430 h

INPUT

Designing a new 6-axle carrier to equip a self-moving drilling machine

PROCESS

Design of frame, steering geometry and transmission FEA calculation of frame and other main parts Specialized transmission calculation Pneumatic and hydraulic system design Electro-hydraulic actuator system design

OUTPUT

Arrangement drawings and calculation report