Transmission analysis for special industrial machine

Activity duration : 180 h

INPUT

Analyze the transmission of a machine for industrial use in order to limit the critical issues encountered in operation

PROCESS

Analysis of operating conditions, gear calculation, bearing calculation, FEA of critical components, development of proposed interventions on the project

OUTPUT

Calculation report on evaluations made, design update proposals review

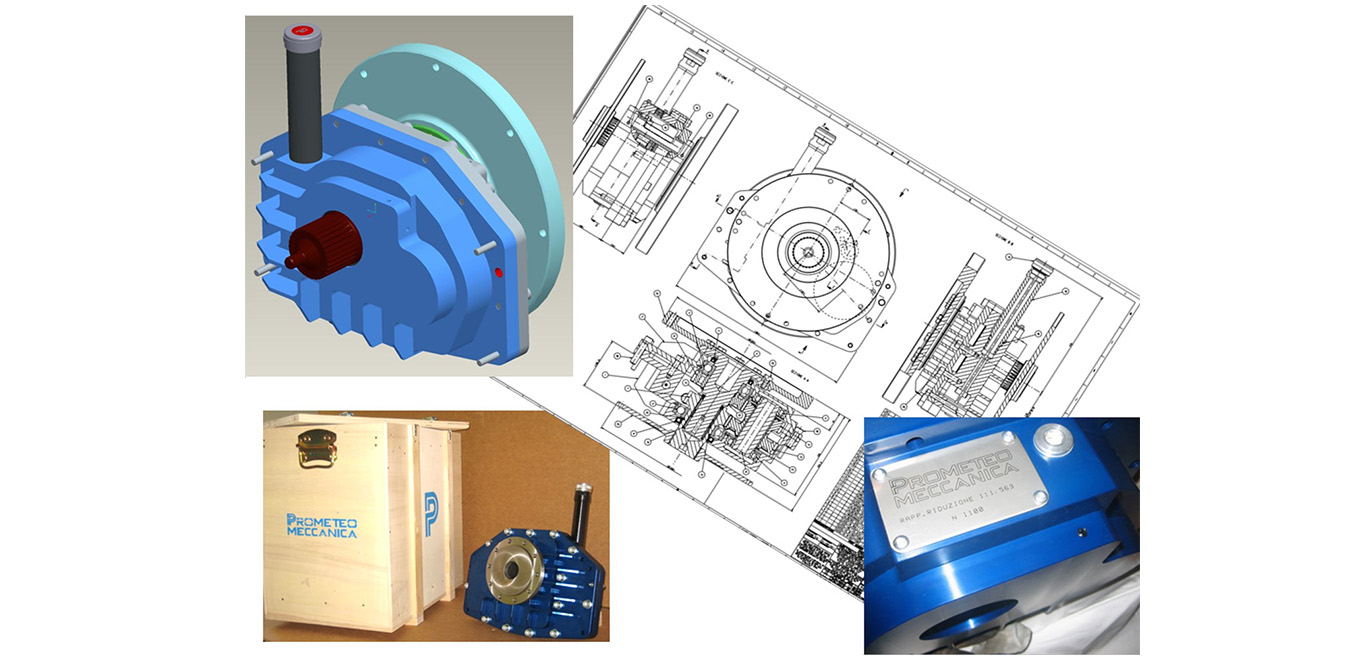

Design of a two speeds gear reducer pre-stage

Activity duration : 1000 h

INPUT

Designing a pre-stage of a two speeds gear reducer for energy field

PROCESS

2D preliminary design and following refining steps Actuator control system design 3D design of all parts and drawings

OUTPUT

General and detailed arrangement designs

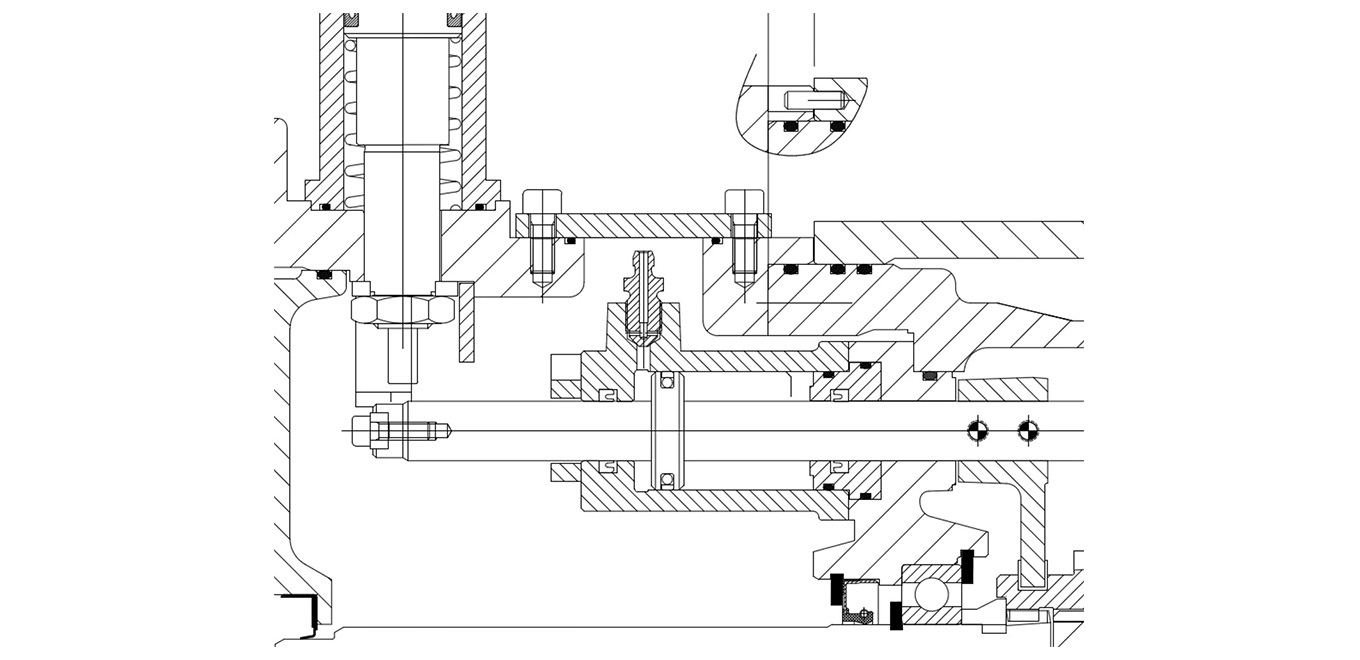

Parallel axis reductor building

Activity duration : 480 h

INPUT

Building a special reductor to equip a prototype machine in energy field

PROCESS

Layout evaluation and drawing up Gears and bearings calculation Arrangement drawings setup Building of parts and assembling of reductor

OUTPUT

Supply of reductor and of arrangement drawings

Design of a two speeds gear reducer pre-stage

Activity duration : 250 h

INPUT

Designing a bevel gear pair for industrial applications

PROCESS

Drafting preliminary study; calculation of bevel gear and bearings according to a given load spectrum; FEM calculation of shafts; drafting final study

OUTPUT

Final study table; calculated component calculation report

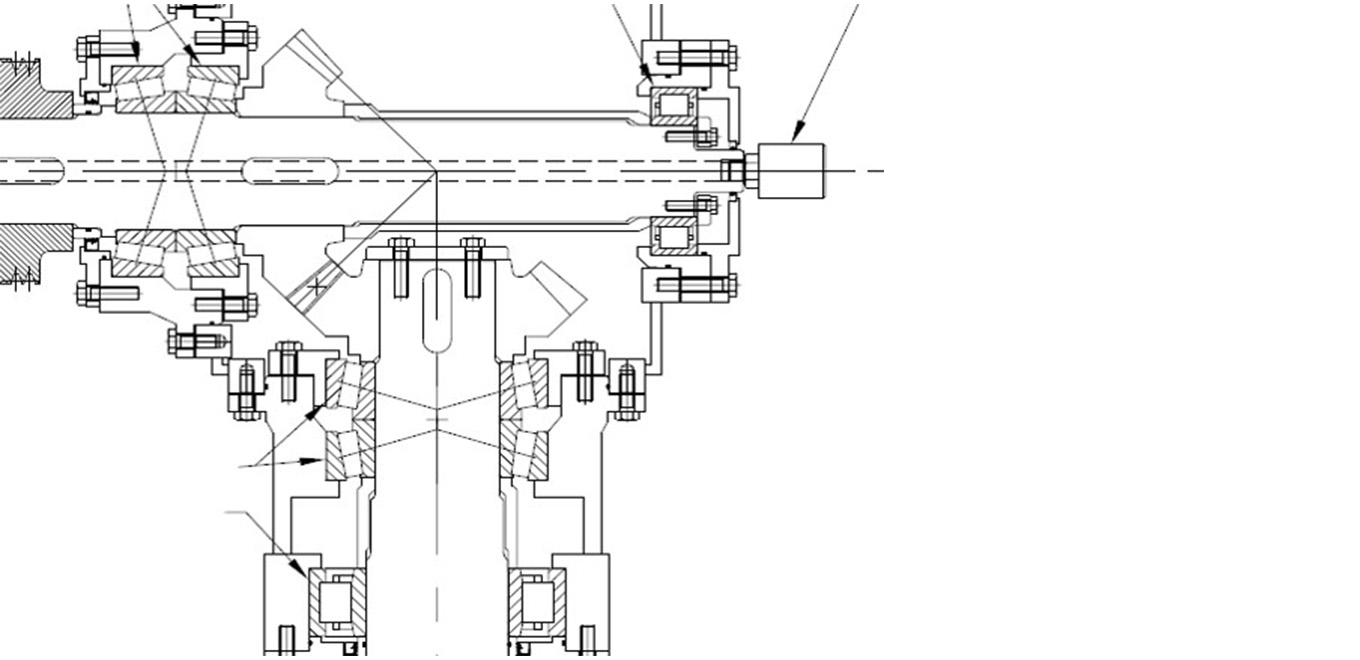

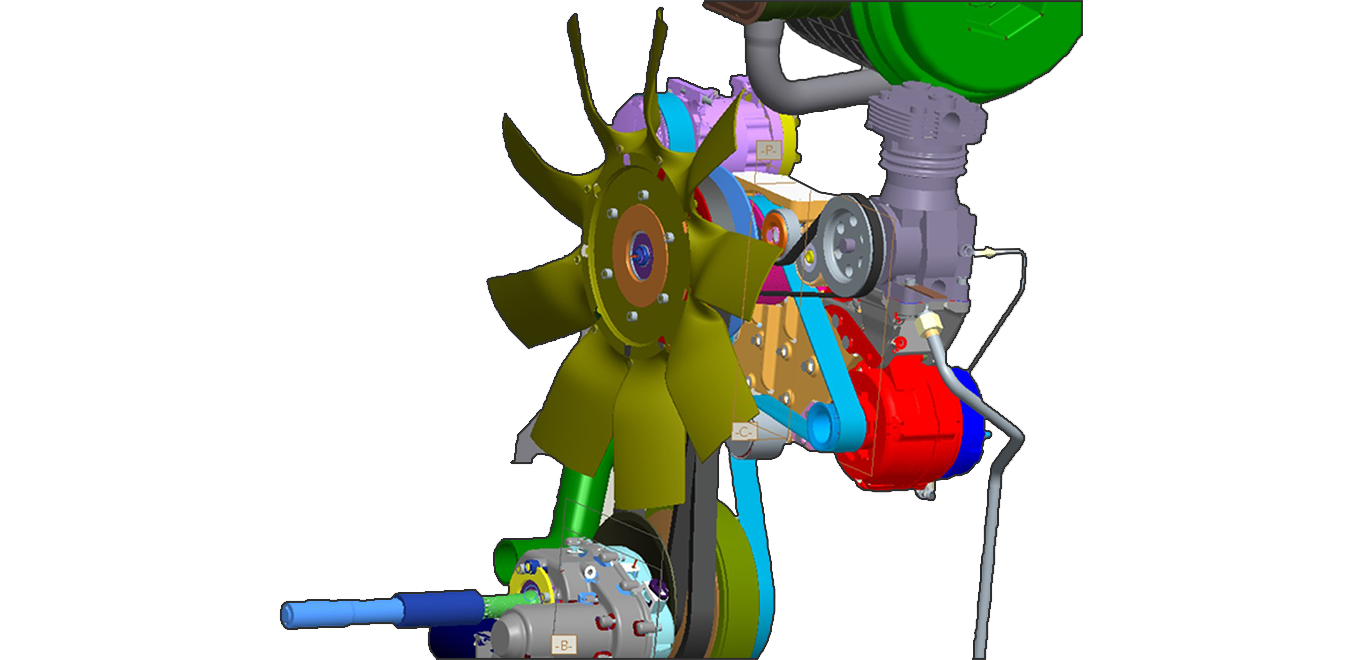

CVT cooling system design

Activity duration : 800 h

INPUT

Design a cooling system with continued variation of ratio for an energetic plant

PROCESS

Layout and load analysis; Preliminary design and following refining steps; Calculation of all parts of transmission

OUTPUT

General and detailed arrangement designs; Calculation report